Skip to content

Main Equipment

- Ball Mill

Rotating grinding equipment used for material size reduction.

- Driving of Ball Mill

Complete drive assembly including motor, gearbox, and coupling.

Auxiliary Equipment

- Stirrer

Mixing unit used for slurry preparation and material conditioning.

- Vibration Sieve

Screening device for particle size separation.

- Gear Pump

Pump used for lubrication oil circulation and pressure supply.

- Filter Board

Filtration plate used in dust control or slurry filtration.

- Soft Starter

Electrical device that reduces starting current and mechanical stress.

- Bearing (22320CA)

Heavy-duty rolling bearing used in mill and drive systems.

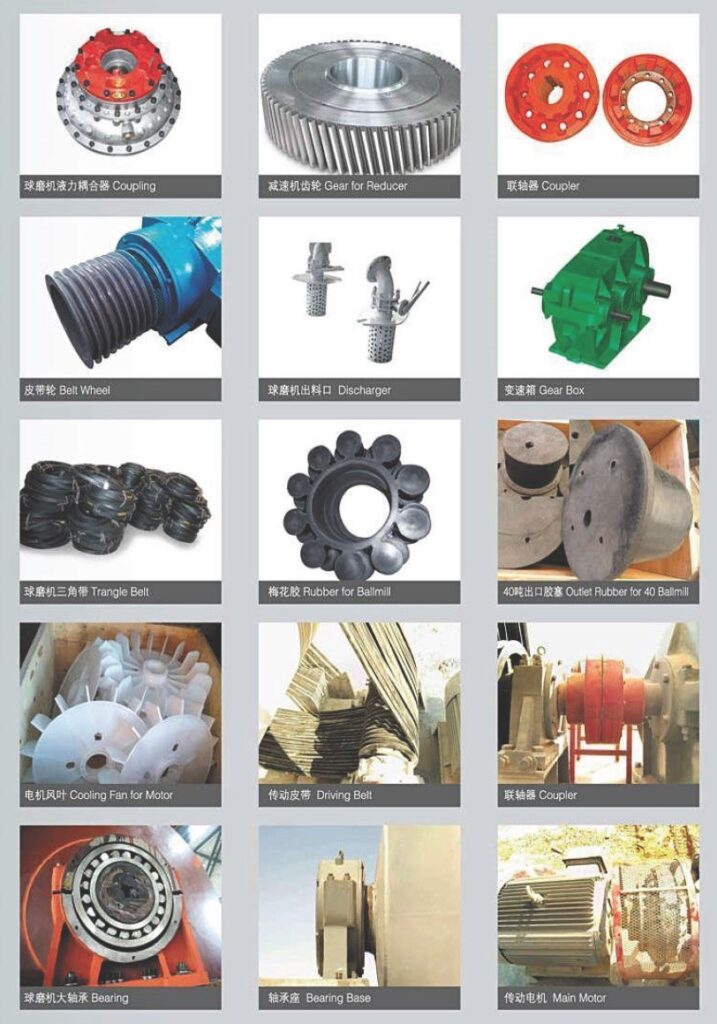

Spare Parts – Ball Mill Series

- Coupling

Torque transmission component allowing limited misalignment.

- Gear for Reducer

Internal gearbox gear for speed reduction and torque transfer.

- Coupler

Flexible connector absorbing vibration and shock.

- Belt Wheel

Pulley used for belt-driven transmission.

- Discharger

Ball mill outlet assembly controlling material discharge.

- Gear Box

Speed reducer transferring motor power to the mill.

- Triangle Belt

V-belt for auxiliary and drive transmission.

- Rubber for Ball Mill

Wear-resistant rubber components for protection and noise reduction.

- Outlet Rubber for Ball Mill

Rubber discharge parts designed for abrasion resistance.

- Cooling Fan for Motor

Cooling fan maintaining motor thermal stability.

- Driving Belt

Power transmission belt between motor and mechanical units.

- Coupler

Heavy-duty coupling used in the main drive line.

- Bearing

Load-bearing rolling bearing for rotating components.

- Bearing Base

Bearing housing ensuring alignment and structural support.

- Main Motor

Primary electric motor driving the ball mill.